Home > News

Home > NewsThe raw materials for making glass are all powder, limestone, sodium carbonate, silica, minerals, chemical colorants, plus the last use of the remaining glass and waste glass fragments. The first step is to make glass. This is the same process as making a“Glass cone”. The raw material is mixed in a furnace and heated to 1600 °C. If made by hand, it is the worker who goes into the furnace and takes the liquid glass from the long pole with the ceramic bowl.

Cut into sections

In industrial mass production, there are openings at the bottom of the furnace, such as the process of pulling... Then a shearing machine cuts the flowing high-temperature liquid glass into segments.

Each section of liquid glass is now a bottle to be distributed quickly on the assembly line, not only because mass production takes into account the quantity produced per unit of time, also consider that today's liquid glass is extremely hot and can be distributed as quickly as possible to prevent damage to the line.

Each section of liquid glass is now a bottle to be distributed quickly on the assembly line, not only because mass production takes into account the quantity produced per unit of time, also consider that today's liquid glass is extremely hot and can be distributed as quickly as possible to prevent damage to the line.

Extrusion molding

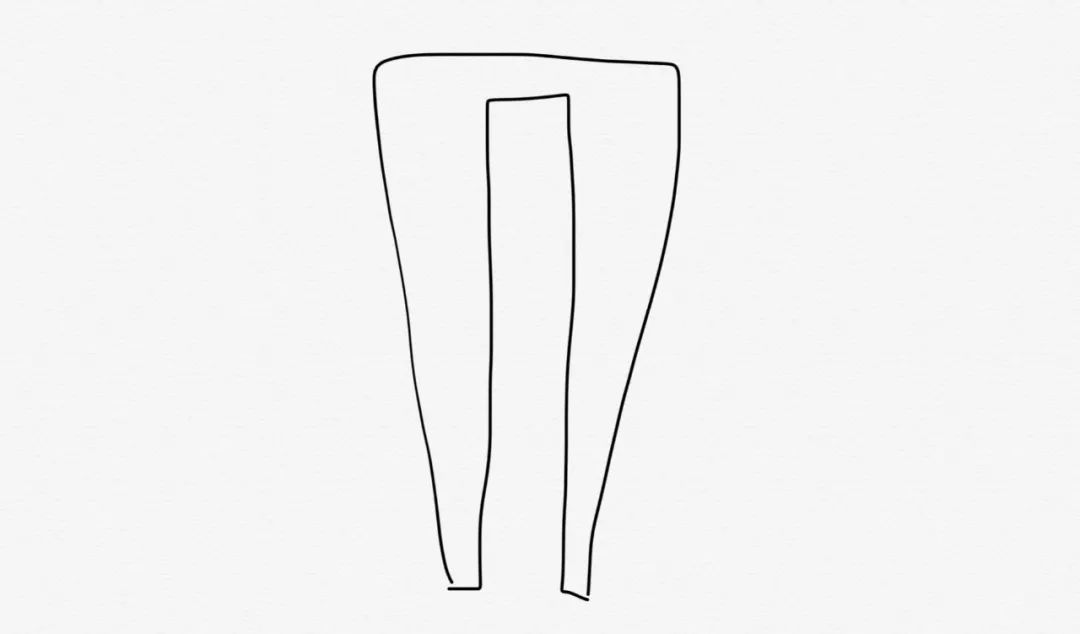

The liquid glass that falls from the conveyor belt falls directly into the first tapered mold and is first made into an inverted tapered bottle, which is inverted in order to make a hollow.

My soul painting again... Looking at the section drawing, it was probably that the outside of the conical bottle was the inverted triangle made by the mould. The cylinder in the middle was also part of the mould. This hollow was used to blow up the bottle in the mould at the back.

Put the tapered bottle into the new mold, directly with industrial gas spray on the bottle of high-pressure air blowing, out is a bottle of wine ~

On the conveyor belt

The finished bottle is“Gently” transferred to the conveyor belt. I don't think I have any misconception about“Tenderness” this time. Who dug the hollow of the puffs? How.

Finally, take a look at a batch panorama. This batch of bottles also needs to be annealed at the back: Heating and cooling gradually releases the pressure inside the glass, making the bottles less likely to break as a whole. After that, we need to check the size of the bottle.

The glasses and bottles that looked particularly exquisite were made of higher quality materials and more complicated manufacturing processes. There were some internal foam patterns and so on. It seemed that the majority of them really had to be done by hand, beauty this thing, it can also see the experience ~